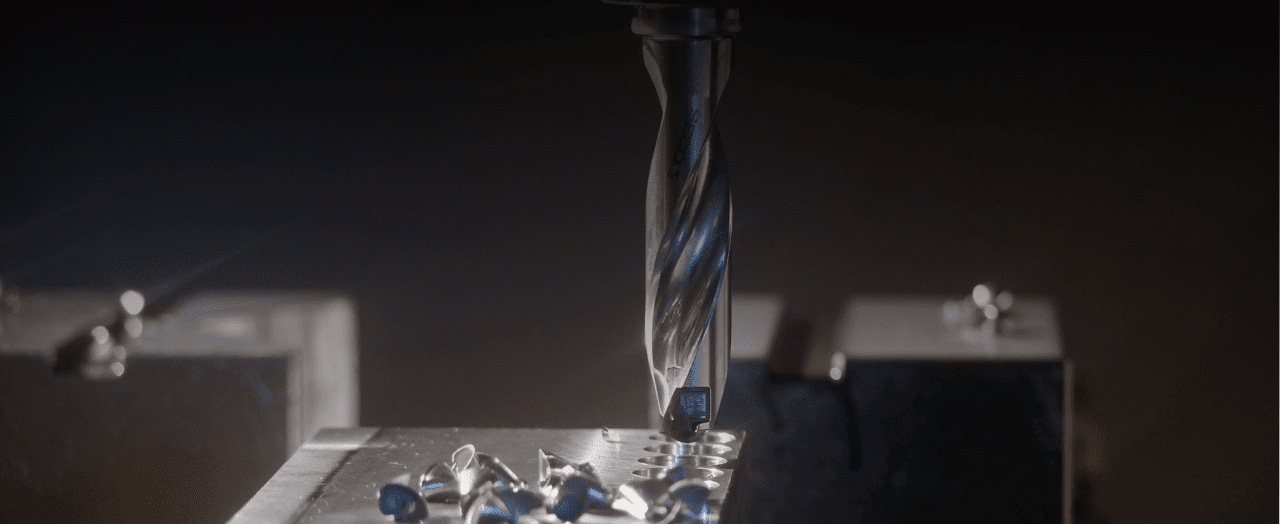

Holemaking

When it comes to Drilling, selecting the most appropriate tooling and machining strategies for your application is critical. Therefore, we offer one of the industry’s most comprehensive selections of drilling tools. So, whether your focus is on volume, accuracy, or cost savings, we have the best offer that is perfect for your needs.

Mulph provides a full range of drilling products, including solid carbide drills, exchangeable tip drills, Gun drills, and indexable insert drills. This wide portfolio of products provides solutions for all applications and workpiece materials across all industry segments, including automotive, energy, medical and more.

Carbide Drills

Carbide drills provide faster cutting rates, longer tool life, better positional and dimensional accuracy, and improved surface finish. Shorter cycle times and tighter tolerances translate into maximum machine utilization, better part quality, and optimum hole-making cost savings.

HSS Drills

Carbide or HSS? The competencies of tool materials are clearly defined – and carbide as the tool material for drilling tools has nowhere near been able to establish itself in all fields of application. Particularly with small and medium series production, with unstable machining conditions and always when toughness is required, users continue to rely on drilling tools in high-speed steel (HSS/HSCO).

Gun Drills

For a diameter-length-ratio from 15xD one generally refers to gun drilling. Gun drills are for example applied for the machining of camshafts, crankshafts, drive shafts, injectors, drill pipes for oil production, in the medical and the food industry. Dependent on the requirements of the hole, the machine conditions, the batch size, and the drilling depth Mulph determines the most economically efficient tool option.

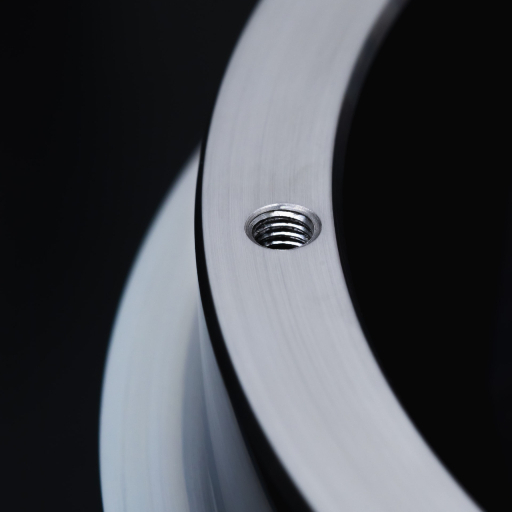

Exchangeable Tip Drills

Mulph provides the exchangeable tip drills that incorporate geometries and coatings that ensure high performance and productivity while minimizing cost by eliminating the need to regrind or replace drills. Additionally, the ability to change tips for different workpiece materials and application requirements reduces the amount of tooling inventory that must be kept on hand