Mulph, Solutions base Company, offers individual needs and requirements of our customers in order to make their business successful. Here the Technology Centre is the front-line base. It is fully equipped with advanced knowledge, technologies as well as having a team of highly experienced technical staff members.

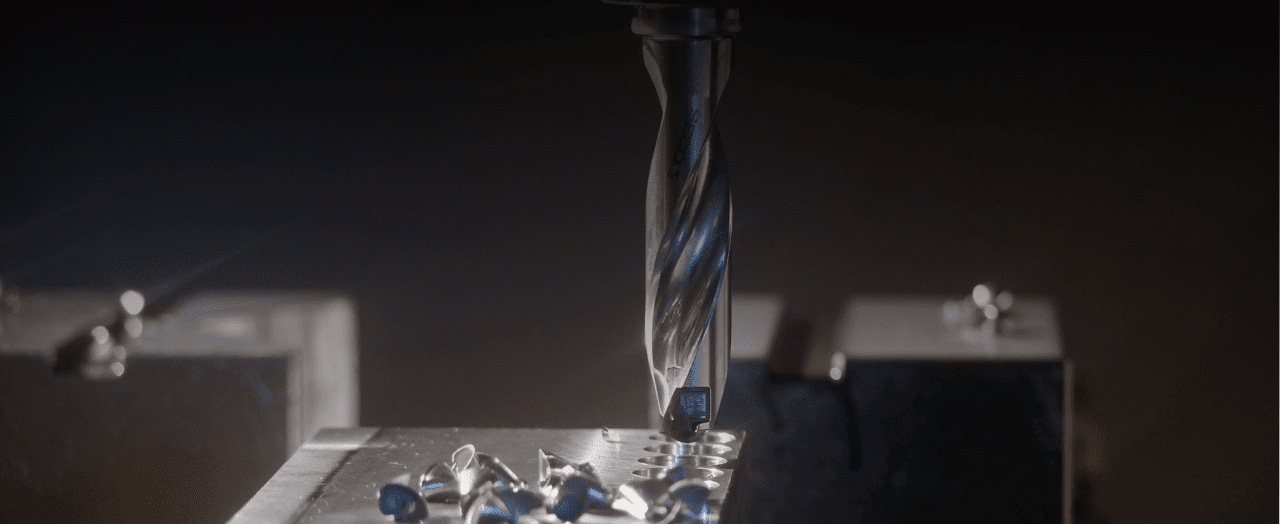

Our product for new machine technology to deliberately vibrate the tool in relation to the cutting direction is an effective way of breaking chips. This reduces production costs by reducing chip entanglement.

Our solution benefit for Thermal conductivity has been improved by optimizing the grain size and therefore reducing the boundary contact. This optimization reduces the temperature of the cutting-edge during machining.

What is Turning?

The figure on the right shows the condition of a cutting-edge during machining. The cutting edge cuts the workpiece and chips are produced. The temperature at the top of the cutting edge becomes as high as 800°C because of impact and friction.

Steel turning is much about continuously refining your current machine set-up. However, it is of major importance to explore new possibilities and discover new technologies and methods. As an example, by applying the all-directional turning method you can reach significantly faster metal removal rates and more than a 50% productivity increase.

Cemented carbide grades that can withstand these high temperatures are the most successful. Carbide formed into different configurations are the most popular, and they are called indexable inserts. Indexable inserts are used for various shapes of holders and selected according to shape of the workpiece and cutting mode.

There are many parameters to consider when choosing turning inserts. To maximize metal removal rates, look for a tough substrate resistant to plastic deformation and a post-treatment that performs well in intermittent cutting operations. Be sure to select a coating that delivers consistent and predictable performance, improved wear resistance and long tool life.

Find your turning inserts and grades based on material?

Turning inserts and grades for 5 group Material: Whether you are looking for turning insert grades for unmanned production or custom-made components, we have reliable insert grades that offer predictable tool life, high machine utilization and the surface quality you need.

Our solution is for ISO P, M, K, S, N, H Material and according by:

Finish, Sem-Finish, Medium, Rough and Heavy Rough with best choice Grade and Chip Breaker with clearly Cutting data for all Process.

Hard part turning with new generation CBN

Turning hardened steel calls for super-hard insert grades. Whatever your component or requirements for surface finish, you will find productive insert grades here that can withstand high temperatures and cutting forces and still retain their cutting edges.

This CBN grade is your first choice for case and induction hardened steels. With its medium content of boron nitride, it is suitable for light to medium interrupted cuts.

Hard part turning is usually a finishing or semi-finishing process with high dimensional accuracy and surface quality requirements.

Component materials are case hardened steel or induction hardened steel. Typical machining challenges with these materials are surface and dimensional tolerance demands with competitive tool life. The new generation CBN grades are specifically designed to handle these challenges in the most efficient way.

Benefits and features

- PVD coating with good fracture resistance

- Stable and predictable tool life

- Efficient machining with good surface finish

Turning with new generation PCD

First-choice grade for roughing and finishing of aluminum alloys. This uncoated carbide grade features a unique combination of excellent abrasive wear resistance and edge sharpness.

Our non-ferrous insert grade assortment consists of uncoated, PVD-coated carbide and crystalline diamond grades for various machining conditions. Use the information below to find the right grade for your production.

Benefits and features

- Roughing and finishing

- Long tool life

- Excellent finish surface