MULPH has a comprehensive portfolio of products and services. As such, individually designed custom tools and high-performance standard products are used to create machining solutions that optimally address the requirements for process reliability, precision and cost-effectiveness.

Supplemented by intelligent services, the customer receives a complete package for the machining process.

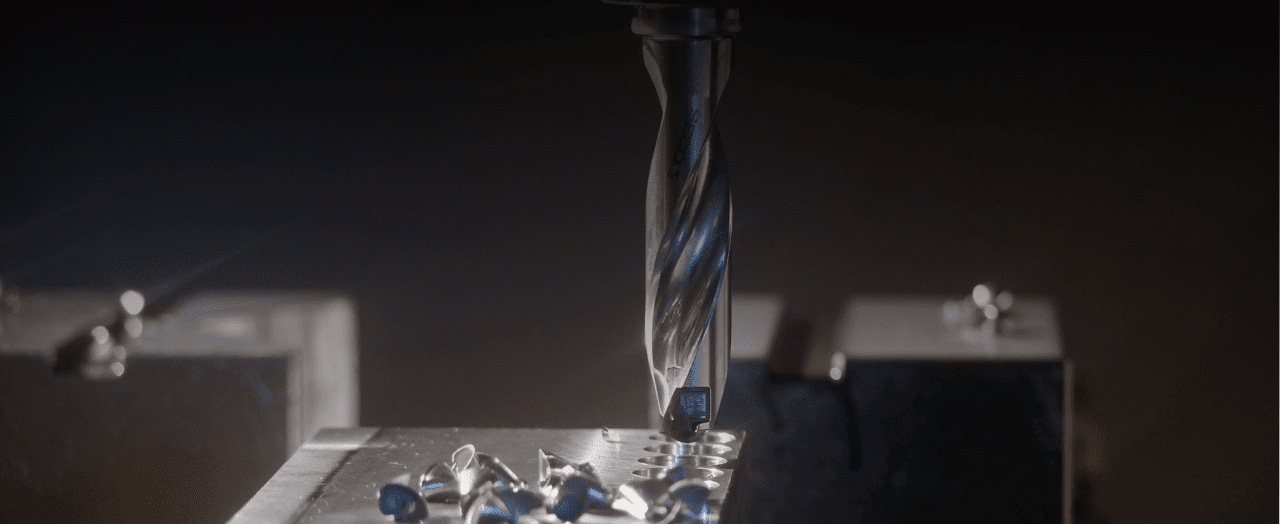

Milling

In the area of milling, MULPH tool experts have developed numerous machining solutions in recent years. The focus has been on tools adapted to the related customer requirements. Along with these individual tool solutions, however, the usage of high-performance standard tools plays a major role in many applications, therefore a comprehensive standard program has evolved from these custom tools.

MULPH offers a suitable tool for every milling task, on the one hand end milling cutters with fixed cutting edges, on the other hand milling cutters with replaceable inserts. All types of machining – whether general machining operation such as groove milling, face milling, shoulder milling, for roughing and finishing, or special machining operations such as trochoidal, high feed or plunge milling – are covered with innovative tool solutions.

For Every Material

Along with the type of machining operation, the workpiece material is the most important criterion for selecting a suitable milling cutter. Along with tools for machining steel, cast iron and aluminum, the program from MULPH also includes solutions for the cost-effective, reliable milling of titanium, super alloys, plastics and composite materials.

Custom Solutions

Carbide or HSS? The competencies of tool materials are clearly defined – and carbide as the tool material for drilling tools has nowhere near been Special machining tasks require special tools. For this reason, MULPH offers custom milling tools individually tailored to the requirements of the customer. For instance, complex shapes and contours can be realized using specifically designed milling cutters, or machining times and tools changes reduced using combination tools.

High-performance Coatings and Grade

A crucial criterion for the service life of the tool and optimal machining results is the coating of the cutting edges. MULPH offers a large selection of substrates and coatings, each matched to the specific machining case.

End Milling Cutters with Fixed Cutting Edges

The high-performance end milling cutter program from MULPH ensures excellent, reliable results during all machining tasks. The focus is on cost-effectiveness and product quality, along with meeting customer requirements.

The end milling cutter program from MULPH includes shoulder milling cutters for groove milling, roughing, finishing and trochoidal milling, as well as milling cutters for high feed, plunge milling, profile milling and chamfering.

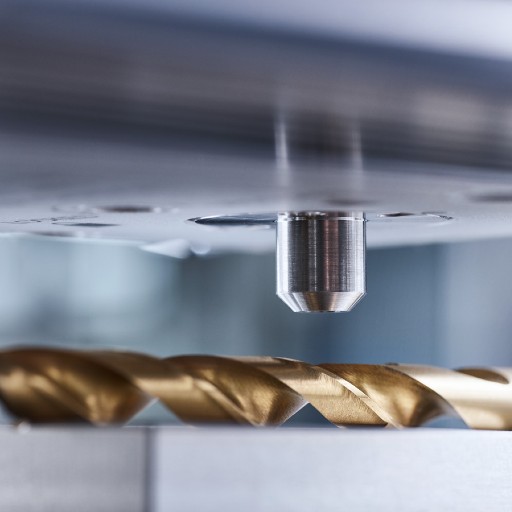

Additional set-up costs are saved with the replaceable head milling cutter program Mill. Due to the easy, safe handling, the milling heads can be replaced directly in the machine tool.

Irrespective of whether you need a cost-effective milling cutter for universal machining or an Expert for a complex machining task – MULPH offers the right tool and solution.